Brake System Tech Guide

The braking system of a vehicle is often neglected when it comes to potential upgrades. Braking improvements donít offer the thrills of a high performance modification, or the serious eye candy of an appearance improvement. However, that certainly doesnít mean that a few brake upgrades thrown at the braking system are a waste of time either. Braking improvements can help a stock vehicle, but are especially important when more power or track duty enters the equation.

The Braking System Explained

One must first understand the basics of the braking system, to fully understand where improvements can be most beneficial. While through the years, the braking components on the Mustang have varied somewhat, the general basics remain the same.

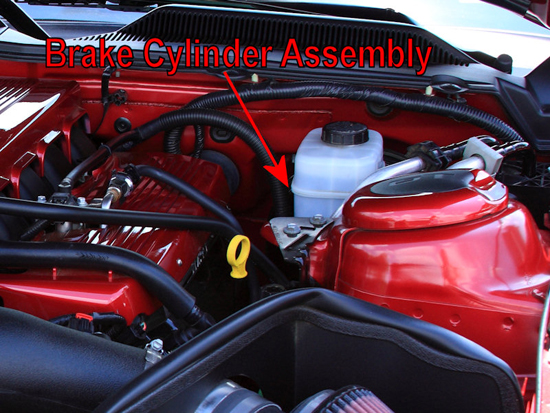

The brake cylinder assembly, located between the engine and the driverís side fender of your Mustang, responds to the brake pedal being pushed inside of the car. Above the cylinder assembly is a brake fluid reservoir. The reservoir is usually semi-clear plastic, allowing you to easily monitor the level of fluid inside of it. As the pedal is pushed, brake fluid is pushed through the tubing to the brakes located at each wheel. This fluid in turn pushes the pistons in the brake calipers, forcing the brake pads to contact the rotors and induce friction. This friction slows the car down.

The brake cylinder found in the Mustang is split into two sections, the master cylinder and the slave cylinder. The master cylinder controls the front brakes, while the rear is controlled by the slave cylinder. The hydraulic lines in modern anti-lock brake equipped cars first travels to the anti-lock brake controller which can control the pressure in the brake lines going to each wheel to help prevent the individual brakes from locking up. It does this based upon feedback provided by a sensor positioned at each wheel that Iíll cover a little later.

General Wheel-Area ComponentsAt each wheel, youíll find the braking component that actually performs the majority of the work when the car is stopped. These components are also the items where routine maintenance is generally necessary to replace worn items.

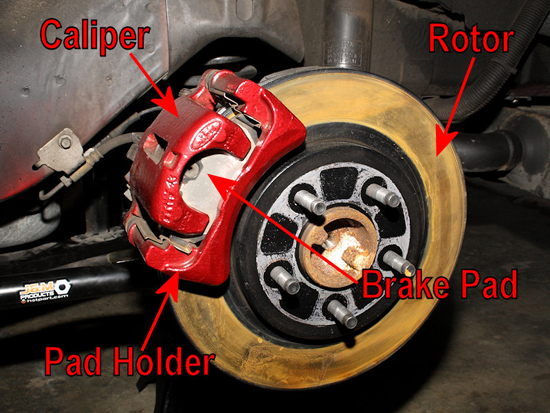

Disc Rotor and CaliperThe largest component found at the wheel is the rotor. It spins along with the wheel, as itís held by the studs for the lug nuts. The brake rotor is a high grade of steel, and will often get a coating of rust very soon after a vehicle is washed, or sits in the rain. Youíll see this often with cars at a dealership waiting to be sold. This is nothing to worry about, and the brake pads will clean the rust coating off the first time they stop the car.

Surrounding a section of the rotor is the brake caliper. Brake pads sit between the caliper and the rotor, and itís the friction between the pad and the rotor that stops the car. Modern Mustangs use a separate holder for the pads, allowing the caliper to be removed with the pads remaining in place. A piston on the backside of the caliper applies the pressure that squeezes the contact surface of the pads against the brake rotor.

Drum Brakes

The Mustang hasnít seen a rear drum brake for many years. However, on older Mustangs, such as the Fox bodies, a front disk and rear drum brake setup was common. Instead of utilizing a disk, the drum brake uses a slightly different configuration, with the pads positioned inside a steel drum. Disk brakes offer more stopping power, and a rear disk brake conversion is often at the top of the list for those with rear drum brakes. On top of that there are more mechanical parts involved with drum brakes, so routine maintenance is a little more complicated due to the various springs and clips needed.

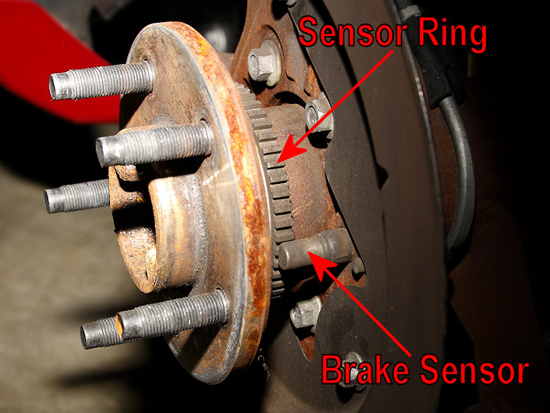

Anti-Lock ComponentsWith the introduction of anti-lock brakes, a few additional components were installed at each wheel. These are a toothed speed sensor ring and a speed sensor. The sensor sees the teeth passing by it, knowing that this means the wheel is rotating. When the brakes are applied and the sensor sees that the teeth are not longer moving by the sensor, it knows that particular wheel has locked up. The anti lock control unit will then pulse the braking power to that particular wheel.

As a side note, the anti-lock braking system is also used by the traction control system as well. If the sensors indicate the wheels are spinning too fast for the carís actual speed at the time, power from the engine is restricted until the wheelspin is corrected.

Popular Upgrade Options and Choices

Brake Pads

The factory brake pads can often be noisy, as they have a tendency to squeal when applied after the car has several thousand miles on it. They also produce a lot of brake dust especially on the front of the car, as the front brakes work harder than the rear. While braking performance from the stock pads is much improved in the newer models than in older Mustangs (Fox-Body owners know exactly what I mean), those who push their cars harder will undoubtedly look for more braking power and less braking fade when repeated high speed stops are made.

There are several aftermarket pad options to address these concerns. Carbon-based pads such as the HPS pads offered by Hawk are an example of this. If youíre looking for the ultimate in stopping power, and a near complete elimination of brake dust, then ceramic-based pads may be an even better option. Ceramic pads provide quiet, powerful, and near dust-free operation that is superior to even the best carbon-based pads. When compared to stock replacement pads, high performance pads are a little more costly, but well worth it if youíre looking for improved operation.

Conversion Kits

Improved pads and rotors will help you enhance your carís braking ability, but it will only take you so far. If youíre aspiring to move to the next level, conversion kits are the way to achieve this. Think of a conversion kit as a supercharger for your brakes, giving you a substantial increase of 50% or more stopping power. Conversion kits vary widely in price, depending upon the route you wish to follow. Ford offers the upgrades found on its special edition Cobra and Mach I Mustangs, while renowned companies such as Brembo offer high end conversion kits that offer the ultimate in stopping power.

Brake Lines

Another popular upgrade option is aftermarket brake lines. The factory brake lines are often rubber-based, which tends to flex under heavy use. Aftermarket lines that utilize stainless steel with materials such as Teflon do not flex and expand under the extreme pressures the lines see when the brakes are applied heavily. The result is better braking response, and a much firmer feel at the pedal.

Rotors

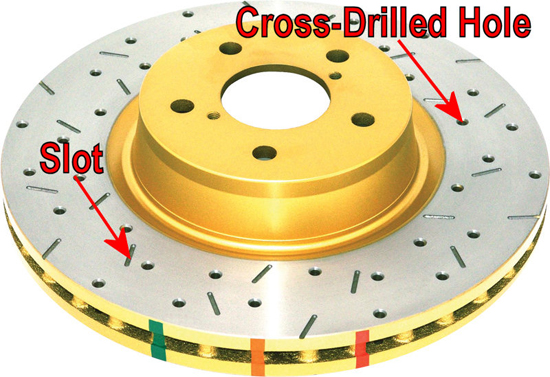

Brake rotors can be replaced as part of a conversion kit, or as a part of their own. Heat is a byproduct of the friction between the rotor and the brake pads. To enhance braking power, youíll want to combat the heat. Aftermarket rotor manufacturers do this in a variety of ways. First, they may use a different grade of metal for the rotor. Then techniques such as cross-drilling or slots, or maybe even a combination of both, also help provide more surface area and better airflow to aid in cooling.

One thing to keep in mind with aftermarket rotors is maintenance. Some shops will not machine slotted or cross-drilled rotors, which may make maintenance a little more trouble than it would be with stock components. So plan ahead, and make sure you have plans for when that day arrives.

Cooling Kits

Youíll also find various brake cooling kits on the market that use air to cool the brakes. Generally this is performed for the front brakes, as they tend to do most of the work. The kits usually use openings that were designed for fog lights, or maybe even part of the openings that direct air to the radiator. Then ductwork channels the air towards the brake rotor and brake pads.

Line Lock/Brake ControlThe drag racing crowd will often use a unique brake accessory to help facilitate heating up the tires during a burnout. Often referred to as a ďline lockĒ, the Brake Control is used to lock the brakes on the front wheels in place to hold the car still during a burnout. To do this, a solenoid is activated by a switch after the brake pedal is pressed. The solenoid then holds hydraulic pressure on the front brake lines, in the same manner if you had kept the brake pedal pushed down. The difference is that the rear brakes are not activated. This saves wear and tear on the rear brake components when compared to trying to use the entire braking system to hold the car still for a burnout. It also allows the rear tires to turnover easier than with the brakes applied which, in turn, does a much better job of heating the tires up for starting line traction.

Caliper Paint/Covers

If youíre looking for a way to enhance the appearance of your Mustang, but donít want to shell out the cash for new brake equipment, caliper paint or caliper covers may be just what youíre looking for. The Dupli-Color kits are a good example of caliper paint, although there are many different options available. Some manufacturers even offer caliper paint that is an exact match to the exterior paint on your car.

Another alternative is caliper covers. Caliper covers are made to fit over your existing calipers, giving them the appearance of an aftermarket caliper. They also help reduce the amount of brake dust that reaches the wheel. Installation only takes a few minutes, and therefore even easier and less time consuming than painting your existing calipers.

As you can see, thereís a lot more to the braking system than simply a set of pads and rotors. Thereís also a whole new frontier that is ready and waiting on upgrades should you have the need or desire. So next time you have a little cash burning a hole in your pocket due to being bit by the upgrade bug, remember your carís braking system. There are several upgrade options that can easily set your car out from the rest of the Mustangs on the road!