Nitrous Oxide Tech Guide

Nitrous oxide is a compound that is chemically represented by two parts nitrogen and one part oxygen. While automotive enthusiasts are probably more familiar with its power-enhancing properties, those outside of the automotive hobby may be more familiar with its other common use, which is as an anesthetic. In the medical community, nitrous oxide is more commonly known as laughing gas, and is used as a general anesthetic in the medical and dental fields. While there are minor differences in the medical grade of nitrous oxide and what’s used in cars, they are essentially one and the same. Obviously, we’ll be focusing on its uses regarding internal combustion engines.

HistoryThe use of nitrous oxide in combustion engines dates back to WWII. The German Air Force experimented with the use of nitrous in their planes, in an attempt to gain an advantage over the Allied forces. The Germans were hoping to use nitrous to increase their combat planes performance at higher altitudes, but overall, its use ended up being limited to reconnaissance and bomber aircraft. Later, the British tried to use nitrous in some of their fighter planes as well.

In later years, nitrous found itself being used in drag racing, as well as during the 50's and 60's muscle car era. Racers were always looking for an advantage, and nitrous was a cheap power option which and could be hidden fairly easy. This made it ideal, if one wanted to keep a potential advantage secret. In turn, this led to the association of nitrous being “cheating”, which still haunts its use in the minds of many.

Nitrous is widely regarded as one of the best “bang for the buck” upgrades. The entry level costs associated with a nitrous installation are much cheaper than a supercharger, and can provide just as much horsepower. In fact, both nitrous and supercharging are more similar than one might think. Both are considered power-adders, and both are simply different methods of accomplishing the same task. That task is to inject more air into the engine’s cylinders, in an attempt to increase power output.

Basic Nitrous System ComponentsThe Bottle

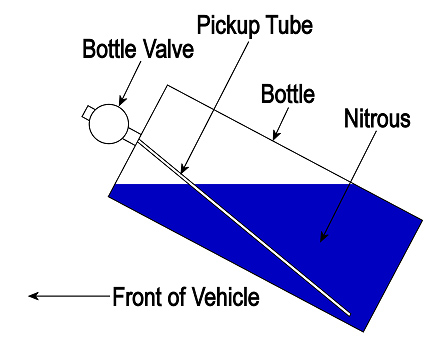

A typical nitrous system has six main components. The first of these is the nitrous bottle. Nitrous oxide is stored as a liquid in a cylinder that’s referred to as a bottle. The most common size bottle is a 10 lb. bottle, although there are several sizes that can be used. The bottle is normally mounted at the rear of the vehicle, with the valve handle pointing to the front of the vehicle. The top of the bottle is generally higher than the bottom of the bottle. This positioning is important for a reason. Remember that nitrous oxide is stored as a liquid, so the goal is to have the pickup tube inside the bottle, fully immersed, so that there’s no interruption in the delivery of nitrous. As the vehicle launches, the front of it lifts. With the top-high/bottom/low set up, the pickup tube will remain immersed in the liquid nitrous. The illustration below shows an example of this.

In some situations, it may be necessary, or desired, for the bottle to be oriented differently. In these cases, the pickup tubes positioning should be considered and altered if needed. In some circumstances, the pickup may even be removed, and the bottle mounted upside down.

Feed Line

The nitrous feed line carries the nitrous from the bottle, through the trunk bottom, to the front of the car, stopping at the solenoids. This line will be routed under the car, and it’s important that it’s kept away from areas that may cause it to become damaged. You’ll also have a vent tube that connects to the bottle, which will be routed out of the car. Usually, this goes through the trunk bottom in the same manner as the feed line does. The vent tube allows the nitrous to exit the cabin of the car, should the bottle’s safety valve fail. An entire bottle of nitrous venting inside the car would be a very dangerous situation.

Nitrous Solenoids

The solenoids control the flow of the nitrous, as well as the extra fuel needed, if a wet-nitrous system is being used. In the past, nitrous solenoids were essentially the same, and easily recognized under the hood. In more recent times, they have become more complicated. Sometimes the traditional solenoid is shunned, in favor of a management unit that regulates the flow of nitrous and fuel, if needed. Regardless, the purpose is still the same. Send the nitrous towards the engine when called upon to do so.

Jets

Jets are small items that resemble nozzles on a garden hose sprayer, although at a much smaller size. The jets allow you to control the rate of nitrous, and fuel for wet-nitrous kits, into the engine. The jets are often categorized by the amount of horsepower they’ll add. So adding horsepower is as simple as swapping the jet that’s used in the system.

Switch

The switch is used to activate the system, and begin the flow of nitrous. In reality, there is often more than one switch used, forcing several criteria to be met before the nitrous begins to flow. When discussing the basics, however, they’re all part of the same genre of component. Falling into the category of possible switches are: the wide open throttle switch, windows switch, and boost switch. Several of these are often used together.

Injector Plates/Nozzles

Even after the solenoid of management unit allows the flow of nitrous, there must still be a way to direct the nitrous into the engine. This is the job of the injector plates or nozzles. Depending upon the system you’re installing, you may use a plate, or a nozzle, as an exit point for the nitrous. Regardless, the purpose is the same, which is to provide you a method to feed the nitrous, and possibly fuel, directly into the engine.

Basic Nitrous System Operation

A basic nitrous system operates as follows. The bottle valve is opened. Then the driver activates the system, by arming the main power switch. Then when either the car is at wide open throttle, (or reaches a specified RPM with a window switch) the solenoids or management unit are activated. This allows the nitrous to flow into the engine via the injector plates or nozzles. When the liquid nitrous is exposed to the atmosphere, it changes from a liquid to a gas.

The change from a liquid to a gas causes a large drop in the intake temperature of the engine. The result is a much denser charge of air, allowing the engine to burn more fuel. Remember that an engine is nothing more than a big air pump, and the way to achieve more power is to simply stuff more air and fuel into it. This is the basic concept of any power-adder, such as nitrous oxide, supercharging, or even turbo-charging.

It’s important to add the proper amount of fuel to the motor, as without it, the engine would run dangerously lean. How the extra fuel is added will vary with the type of nitrous system used.

Dry-Nitrous System

A dry-nitrous system is one that injects only nitrous into the engine’s intake. Since you’re only controlling the flow of nitrous, there’s a single nitrous solenoid and no solenoid is used to control the fuel. This is where “dry” comes from, as you are only adding air (nitrous oxide) into the system. However, there is still a need to add fuel to the combustion chamber. This extra fuel is added through the stock fuel system, typically by increasing the fuel pressure.

Wet-Nitrous System

A wet-nitrous system uses both nitrous and fuel solenoids to inject both nitrous and fuel into the engine’s intake. Wet systems are much more common on nitrous-equipped cars.

Other Common Nitrous Components

There are many other components that can be used with a nitrous system. Their objectives are safety, convenience, and more consistent operation of the system. The more common of these components are listed below.

Bottle Heater/Bottle Blanket

For proper and consistent operation, the bottle pressure must be at an optimum pressure of 900-950 psi. Both a bottle blanket and bottle heater are different ways to achieve this. A bottle blanket helps to trap heat in the bottle when cold, and to help shield it from the sun when it’s warm. Its use is more limited than a bottle heater in cold weather. A bottle heater does exactly what you think it would do, which is heating the bottle up if it’s too cold and the pressure too low.

Pressure Gauge/Regulator

Without a pressure gauge, it would be impossible to know whether you need a warmer bottle or not. While typically mounted on the bottle, some installations also use a gauge visible to the driver. In such cases, the driver often has a fuel pressure gauge as well, allowing the fuel pressure to be monitored too. A pressure regulator can also be installed to automatically vent the pressure to a desired level, in the event it’s too high.

Purge Valve

If you’ve been to the drag strip and seen a car blow out what appears to be steam from around the hood, you’ve probably witnessed a nitrous purge. A purge valve kit is what it takes to do this, and while it can be intimidating to the driver beside you, it serves a couple of functional purposes as well. The first is to rid the system of any air, making sure that only a pure nitrous oxide mix is present. Air in the line can cause an engine to run rich and bog for a fraction of a second, hindering performance.

The second function of a purge valve is to reduce bottle pressure. Consistent runs require a precise pressure, and having the pressure a little high before you get to the starting line allows you to purge the system and bring the pressure down to where you want it. Relieving pressure is quick and easy, but raising it is not. The track isn’t going to wait on you to heat the bottle up while staging, but the mere seconds a purge requires can easily be performed during this time frame.

Remote Valve

A remote valve allows you to open and close the nitrous bottle with a simple flick of the switch. This is convenient for those times you may want to open the bottle, while never leaving the driver’s seat.

Wide Open Throttle Switch

The use of nitrous requires a few criteria to be met. One of those is that the engine should be a full throttle when the nitrous is in use. To ensure this is the case, a wide open throttle switch is often employed. The switch can vary, from a mounted switch to an electronic device wired into a computer system on drive-by-wire cars. Regardless, the result is the same, even when the nitrous system is armed, nitrous will only flow if the engine is at full throttle.

Window Switch/Boost Switch

Similar to the full throttle condition, nitrous should only be used at certain RPM ranges. A window switch can be used to accomplish this task. It can be set to only allow nitrous to start flowing at a certainly RPM range, and even shut it off at a second RPM range, to prevent the engine from over-revving in the event of a missed shift. In some cases, a vehicle may use a combination of a supercharger and nitrous. When that is the case, a boost switch may be employed to limit nitrous spraying to a certain boost range.

Advantages and Disadvantages of Nitrous as a Power Adder

Nitrous has a couple of distinct advantages when compared to other power adders. First and foremost are the upfront costs associated with purchasing and installing a system. Superchargers start around $3,500 and go up from there. A nitrous kit generally starts around $500, and even with several accessories is still just a fraction of the cost of a supercharger.

The second advantage is that, unlike a supercharger or turbo, nitrous cools the intake air. A supercharger or turbo compresses the incoming air, and when air is compressed it heats up. The hotter air reduces the availability of power from a cooler charge and raises operating temperatures. This is one reason why higher supercharging and turbo applications tend to gravitate towards the use of an intercooler. The cool intake charge from nitrous doesn’t suffer from this problem, helping to maximize the amount of power you’ll get.

Nitrous has one chief disadvantage when compared to other power adders, though, and that is the need to refill the bottle. How long a bottle lasts will vary, depending upon how much nitrous is being sprayed into the motor. Once it’s empty though, you’ll need to refill it. The average price varies from location to location, so you’ll generally find prices of around $30-50 for a bottle refill. You’ll want to plan ahead when looking for a nitrous system, and have a location picked out for getting your bottle filled at. Keep in mind, you’ll need to get the bottle filled before installing, as nitrous bottles are shipped empty.

Nitrous is certainly one of the best options when comparing horsepower to dollars spent. It has suffered many misconceptions about how dangerous it is for the motor. If used correctly, however, nitrous is no more detrimental on your engine than any other power adder. In fact, nitrous is actually less detrimental, because when you’re not using it, the engine is operating under the exact same conditions as it was before the nitrous kit was installed. In the end, if you’re looking for cheap power, nitrous is always going to be an attractive option.