- Shop All

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Coyote Engine Conversion Parts

- Reservoirs & Tanks

- Crate Engines & Blocks

- Serpentine Belts

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Body Kits

- License Plates & Frames

- Bras

- Light Covers

- Bumper Inserts

- Lightbars & Styling Bars

- Caliper Covers & Paint

- Louvers

- Car Covers

- Mud Flaps

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Paint & Headlight Protection Film

- Decals

- Pre-painted Parts

- Decklid Panels

- Racing Stripes

- Door Handles, Covers & Bezels

- Scoops

- Emblems & Badges

- Spoilers

- Exterior Trim

- Taillight Trim/Bezels

- Fuel Doors

- Wheel Accessories

- Grilles

- Wind Deflectors

- Hood Pin Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 2010-2013

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Reservoirs & Tanks

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets & Seals

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Bras

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals & Stripes

- Paint & Headlight Protection Film

- Decklid Panels

- Pre-Painted Parts

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Scoops

- Exterior Trim

- Spoilers & Wings

- Fuel Doors

- Taillight Trim

- Grilles

- Wheel Accessories

- Hood Pins & Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 2005-2009

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Reservoirs & Tanks

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets & Seals

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Bras

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals & Stripes

- Paint & Headlight Protection Film

- Decklid Panels

- Pre-Painted Parts

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Scoops

- Exterior Trim

- Spoilers & Wings

- Fuel Doors

- Taillight Trim

- Grilles

- Wheel Accessories

- Hood Pins & Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1999-2004

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Motor Mounts

- Alternators

- Nitrous Kits

- Batteries

- Oil Pans

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Replacement Serpentine Belts

- Cylinder Heads & Valvetrain

- Reservoirs & Tanks

- Engine Dressup

- Shaker Systems

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Mass Air Flow Meters/Sensors

- Exhaust

- Exterior

- Antennas

- Hood Pins

- Bras

- Hoods

- Bumper Inserts

- License Plates & Frames

- Caliper Covers

- Lightbars & Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals

- Racing Stripes

- Decklid Panels

- Scoops

- Door Handles, Covers & Bezels

- Spoilers & Wings

- Emblems & Badges

- Taillight Trim & Bezels

- Exterior Trim

- Wheel Accessories

- Fuel Doors

- Window Tint & Light Tint

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1994-1998

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Cylinder Heads & Valvetrain

- Replacement Serpentine Belts

- Engine Dressup

- Reservoirs & Tanks

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Exhaust

- Exterior

- Antennas

- Hood Pins & Kits

- Bras

- Hoods

- Bumper Inserts

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Racing Stripes

- Decals & Stripes

- Scoops

- Door Handles, Covers & Bezels

- Spoilers & Wings

- Emblems & Badges

- Taillight Trim & Bezels

- Exterior Trim

- Wheel Accessories

- Fuel Doors

- Window Tint & Light Tint

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1979-1993

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Cylinder Heads & Valvetrain

- Replacement Serpentine Belts

- Engine Dressup

- Reservoirs & Tanks

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Exhaust

- Exterior

- Antennas

- Hood Pins & Kits

- Bumper Inserts

- Hoods

- Caliper Covers

- License Plates & Frames

- Car Covers

- Light Bars & Convertible Styling Bars

- Convertible Top Parts

- Louvers

- Decals & Stripes

- Mirrors & Mirror Covers

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Spoilers & Wings

- Exterior Trim

- Wheel Accessories

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

How to Install a Roush Rocker Molding Kit - Unpainted on Your 2005-2009 Mustang

This Mustang Parts Installation Guide Works For

| Tools Required

Installation Time: 3 Hours |

Installation

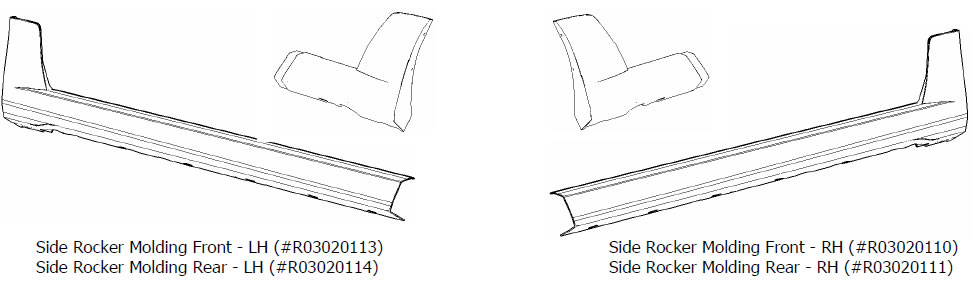

Packaging List for Complete Side Rocker Molding Kit # R03020109 / 112

| Item | Quantity |

|---|---|

| Side Rocker Molding Front - LH (#R03020113) | 1 |

| Side Rocker Molding Rear - LH (#R03020114) | 1 |

| Side Rocker Molding Front - RH (#R03020110) | 1 |

| Side Rocker Molding Rear - RH (#R03020111) | 1 |

| Hardware Kit (#R03020118) | 2 |

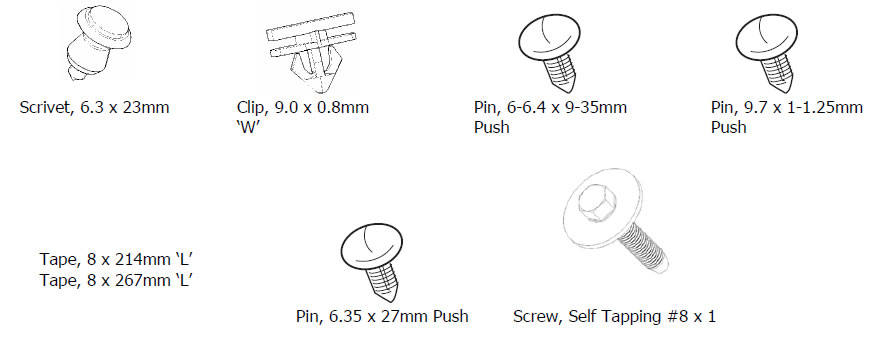

| Scrivet, 6.3 x 23mm | 2 |

| Clip, 9.0 x 0.8mm ‘W’ | 6 |

| Pin, 6-6.4 x 9-35mm Push | 6 |

| Pin, 9.7 x 1-1.25mm Push | 1 |

| Pin, 6.35 x 27mm Push | 1 |

| Screw, Self Tapping #8 x 1 | 2 |

| Tape, 8 x 214mm ‘L’ | 1 |

| Tape, 8 x 267mm ‘L’ | 1 |

| Installation Instructions (#R03020120) | 1 |

Suggested Materials

- Dupont® 2319 Plastic Prep

- Dupont® 2330S or equivalent Adhesion Promoter (for paint)

- 3M 4298 Adhesion Promoter (for double-sided tape)

LIMIT OF LIABILITY STATEMENT

The information contained in this publication was accurate and in effect at the time the publication was approved for printing and is subject to change without notice or liability. Roush Performance Products (RPP) reserves the right to revise the information presented herein or to discontinue the production of parts described at any time.

SAFETY PRECAUTIONS

STOP! CAREFULLY READ THE IMPORTANT SAFETY PRECAUTIONS AND WARNINGS BEFORE PROCEEDING WITH THE INSTALLATION!

Appropriate disassembly, assembly methods and procedures are essential to ensure the personal safety of the individual performing the kit installation. Improper installation due to the failure to correctly follow these instructions could cause personal injury or death. Read each step of the installation manual carefully before starting the installation.

- Always wear safety glasses for eye protection.

- Place the ignition switch in the OFF position.

- Always apply the parking brake when working on the vehicle.

- Block the front and rear tire surfaces to prevent unexpected vehicle movement.

- Operate the engine only in well-ventilated areas to avoid exposure to carbon monoxide.

- Keep yourself and your clothing away from moving parts when the engine is running.

- Do not wear loose clothing or jewelry that can be caught in rotating or moving parts.

- Allow the engine, cooling system, brakes and exhaust to cool before working on a vehicle.

- Do not smoke or use flammable items near or around the fuel system.

- Use chemicals and cleaners only in well-ventilated areas.

- Batteries can produce explosive hydrogen gas which can cause personal injury. Do not allow flames, sparks or flammable sources to come near the battery.

- Keep hands and any other objects away from the radiator fan blades.

- Paint Preparation

- Wipe each part with plastic prep (Dupont® 2319 or equivalent)

- Wipe entire part with tack cloth

- Apply adhesion promoter (Dupont® 2330S or equivalent) prior to color and clear coat applications. This part is made of TPO (Thermoplastic polyolefin) and requires a promoter for paint adhesion.

- Pre-Installation

- Wear eye protection

- Clean area where the RPP rocker will be installed thoroughly before installation.

- Stock Rocker Molding Removal

- Remove rear wheels from vehicle.

- Remove fasteners at front wheel well opening flange, two per side. (Figure A)

- Remove five big push pins and one small per side from bottom of rocker moldings. (Figure B)

- Remove rocker molding from body. (Figure C)

- Clean both right and left hand side rocker areas on vehicle with rubbing alcohol.

- Rocker Molding Preparation

- Apply 3M 4298 Adhesion Promoter, or equivalent, to areas to receive double-sided tape.

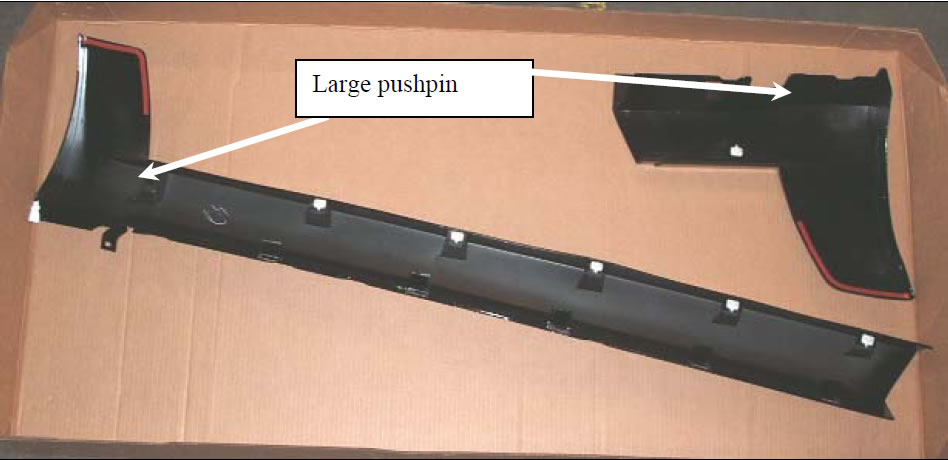

- Install the supplied tape strips to front and rear rocker moldings.

- Peel 2 or 3 inches of the red tape backing tape backing and fold over to make a pull-tab.

- Install ‘W’ clips to front and rear rockers. (Figure D)

- Rocker Molding Installation

- Apply 3M 4298 Adhesion Promoter to the areas on the car where the double-sided tape will mate to.

- Install rear rocker molding to vehicle by positioning to vehicle and engaging ‘W’ clips.

- Install rear front molding to vehicle by positioning to vehicle and engaging ‘W’ clips to body.

- Install pushpins into bottom of front and rear rocker moldings.

- The forward most hole in the front rocker must be folded into place. (Figure E)

- Use the small push pin (Pin, 6.35 x 27mm Push) in the forward most hole in the front rocker

- With all clips and pushpins installed, verify rocker fit to vehicle and continuous gap at front / rear joint.

- Install front rocker molding tape area by peeling off protective backing and positioning on to body, aligning to body features.

- With front rocker molding installed evaluate fit of rear rocker molding for proper alignment and gap at joint.

- Install rear rocker molding tape area by peeling off protective tape and positioning on to body, aligning to body features.

- Install the (2) self-tapping rear mounting screws (#8 x1) into rear rocker and through body flange. (Figure F)

- Install front rocker flange fasteners (Scrivet, 6.3 x 23mm). (Figure G)

- Re-install rear wheels on vehicle.

Figure A

Figure B

figure C

Figure D

Figure E

Figure F

Figure G

Continue Shopping

- Shop all Roush Performance Mustang Parts

- Shop all 05-09 Mustang Body Kits

- Shop all Mustang Body Kits

Dylan I.

Nathaniel F.

Charles M

William L

Benjamin T

Johann S

Warren M

Ronald M

Jim G

Kristen H

Michael N

Jaime C

Alex G

Stacey H

Richard S

Josh W

Ricky I

Phillipe D

Greg W

Erin O

Dustin P

Heather W

Deborah L

Anthony A

Kenny O

Chris G

Bruce C

Kelvin A

Ronald H

Brian T

Anthony E

Daniel B

Ricky I

Linda W

Michael M

Emir H

Doug B

Chris G

Louis D

William S

Stefan O

Johnny B

James J

Noah B

Mac S

Richard M

Dennis S

Noah B

Richard M

Eric J

Michael A

Spencer T

Robert R

Sara A

William B

Erik S

James R

Kary K

John N

Emir H

Jonathan B

Sherry C

Josh W

William N.

Stratis R

Leo S

Joseph W

James C

George Y

Stephen C

David L

Richard A

Charles M

Albert B

Kyle P

Jim W

Walt S

Ronald B

Stephen H

Carlos G

Paul C

Aaron W

Robert S

Valerie J

Richard A

Ernesto C

Robert R

Steven T

Greg M

Jordan C

Ryan D.Customer Support

I grew up a Chevy kid, but when it came time to get a muscle car of my own, I fell in love with Mustangs. Been bleeding blue ever since. Being a Customer Service Rep at American Muscle lets me talk about the cars I love and how to make...

DaveTraining Director

I have been toying with Mustangs since before a driver's license was even an option. I've owned somewhere around 15 and I'm not done by a long shot. It all started with a 175 HP pearl white convertible Fox Body. It sparked my love for Mustang's and that sparked a...

BillCustomer Support

I'm currently a student at Penn State University studying political science. I've run a performance shop on the side for over a year now, and I've been working on cars for 7 years now. I've done transmissions, engines, and suspensions on many different cars. I used to be a Chevy...

GerryCustomer Support

When I retired after working for the city of Philadelphia and Septa I decided it was time to relive my earlier years and buy a real muscle car. (I also took on this job at AmericanMuscle for fun - I love the car and the community and belong to several...

KarenCustomer Support

I am a Mustangaholic. Do not try to cure me, I am perfectly OK with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was...

DuncanMarketing

Got into cars when I was young. Always was into the Mustangs because of the movie 'Gone in 60 Seconds' with the 1967 Shelby GT500 Fast back when I was growing up. I am currently attending Universal Technical Institute for Automotive/Diesel and Ford Fact program. I just started working at...

DannBama Tuning Specialist

I may be the only person to ever brave a winter with drag radials on a Mustang, while still daily driving it. Don’t worry, I finally got them off in the spring (day late and a dollar short, right?), and I promptly finished those tires at our company picnic in...

CraigProduct Development

I have always been around Mustangs in my professional life, either fixing them as a mechanic, selling them at dealerships, or modding them here at AmericanMuscle. Instead of starting right away with the power mods, I started looking more into suspension and weight reduction. I have always dreamed of entering...

LeeCustomer Support

I am a diehard Mustang fanatic. I first fell in love with Mustangs when I was 15 years old and I found a 1966 Mustang coupe restoration project. That was the beginning of my addiction. I quickly added a 1993 Mustang LX 5.0 to my collection which served as my...

JamieCustomer Support

This whole story starts when I was 15 and I had to have a foxbody. So I went out and found the loudest fastest foxbody that 5 grand could buy. When I realized that this thing was a certain death trap I sold it and moved onto the 2000 GT...

HeatherCustomer Support - Lead

I went to automotive school in Exton, PA, and worked as a mechanic for a while. My dad is a huge Ford guy; he used to drag race and my uncles raced motorcycles so I was always in the garage growing up. Working here is nice because it's not as...

Ryan MBama Tuning Specialist

I got my first Mustang when I was 16, a two tone 91 GT red and silver with a sunroof that didn’t leak! And needless to say I was a bit timid to do work on it, I hadn’t modified any vehicle before outside of installing a CD player. I...

DrewCustomer Support

Recently I bought my first home, the selling point for the house was not the amount of land, bedrooms, or bathrooms like how most people would choose a home. I made my choice based on the garage where the mustang sleeps. The garage is completely finished with painted floors, walls,...

Mike JCustomer Support - Manager

My first car was a 1989 Ford Mustang Saleen Convertible that I used as my test car to learn about working on Mustangs. Foxbodies have become my passion and now I pretty much consider myself a Foxbody expert. My dream project car is a Foxbody with a 03-04 cobra swap...

KarenCustomer Support

I am a Mustangaholic. Do not try cure me, I am perfectly ok with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was 13....

BrickPurchasing

I was a customer first - 7 years ago I came in to buy parts, got in an argument with someone about a part, and won. I left with my parts and a new job and I've been here ever since. I knew when I came to work at AmericanMuscle,...

JeffMarketing

I've loved Mustangs for as long as I can remember. My dad was a Camaro guy growing up, but his first work truck was a Ford, and we've been a Ford-only family ever since. My dad is a sheet metal worker/mechanic, so everything I know about my car I learned...

DanCustomer Support

All my other cars were all-wheel drive, my brother had an 04 cobra and i wanted to compete and beat him with naturally aspirated so i went with a mach1 - and beat him. Now he works here too! I got lucky and was able to find one of the...

SandyOperations

I have only driven 2 manual transmission Mustangs, the 1st was the car that taught me how to drive stick shift. The other is my current daily driver. A very memorable moment about my GT500 happened when I purchased a JLT CAI and SCT tuner. I thought the car was...

KarenCustomer Support

I am a Mustangaholic. Do not try cure me, I am perfectly ok with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was 13....

Chris RMarketing

I was raised by a car family. Drag racing and the Ford blue oval were always a huge part of our household. During my high school years, working on cars and participa....err watching street races probably helped further pull my focus from my priorities and I was hooked. After high-school...

LeeCustomer Support

I am a diehard Mustang fanatic. I first fell in love with Mustangs when I was 15 and I found a 1966 Mustang coupe restoration project. That was the beginning of my addiction. When it came time for my wife to get a new car, she had already driven my...

MikeLead Calibrator & Ford Performance Expert

I’ve had 18 Mustangs, ranging from a stock 66 coupe to a low 9-second Fun Ford Weekend” Street Renegade 96 GT that made 888 RWHP. (308 cid motor, Edelbrock heads, intake and topped off with a Paxton Novi 2000R supercharger pushing 30 psi of boost). My best pass in that...

BrianContent Development

Mustangs hold a special place in my heart. My father owned a 65 mustang when he was younger, but a friend wrecked it. The grille pony still sits on his workbench. Until getting my own pony, I had no clue why he would keep a metal horse for so long....

JamieCustomer Support

This whole story starts when I was 15 and I had to have a foxbody. So I went out and found the loudest fastest foxbody that 5 grand could buy. When I realized that this thing was a certain death trap I sold it and moved onto the 2000 GT...

GerryCustomer Support

When I retired after working for the city of Philadelphia and Septa I decided it was time to relive my earlier years and buy a real muscle car. (I also took on this job at AmericanMuscle for fun - I love the car and the community and belong to several...

EthanInventory Control

I've worked here for 3 years now and done pretty much everything in the warehouse from mounting and balancing wheels/tires, driving the forklift, shipping, and receiving. Both my brothers worked here in other departments, keeping it in the family! My car philosophy's pretty simple, I just want to get where...

EXPLORE

CUSTOMER SERVICE

Sign up for Exclusive Deals & Offers

Connect