Supercharger Tech Guide

Without a doubt, one of the most sought-after, aftermarket upgrades for the Mustang is the supercharger. It’s considered by many as the Holy Grail of performance additions, commanding a much higher price tag than an item such as a cold-air intake. The power gains are some of the largest and most rewarding that you’ll ever encounter. This amount of power is what places superchargers at the top of the wish lists of many enthusiasts.

Types of Superchargers

While the types and designs of superchargers have varied over the years, there are really two basic types of superchargers for the Ford Mustang. These are the centrifugal and positive displacement options.

Centrifugal SuperchargersThe centrifugal supercharger became a very popular option for the Fox-Body Mustang, although its first use on the Mustang date back several decades ago. Carroll Shelby starting using Paxton superchargers on certain Shelby Mustangs back in the sixties. These particular Shelbys command a very high price tag among car collectors today.

The centrifugal supercharger is best suited for producing higher RPM horsepower, as it generally starts providing noticeable boost around 3,000 RPM. This made the centrifugal supercharger ideal for the 5.0 Mustang, as that pushrod V8 engine was known for producing plenty of low-end torque on its own.

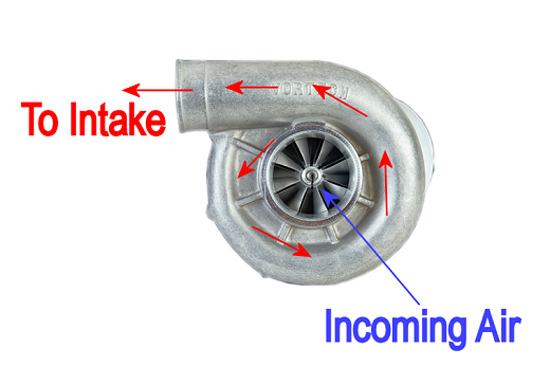

The centrifugal supercharger is placed beside or in front of the engine, with air entering the front of the supercharger. A pulley is mounted directly opposite to the air inlet, and is driven by the engine’s accessory belt system. This pulley spins the impeller, which is found inside the supercharger. The impeller looks like a series of blades, and can be seen through the air inlet. As the impeller is spun increasingly faster, the motor's RPM increases as well, and the impeller produces enough force to overcome the vacuum that normally pulls air into the motor. The supercharger then forces air into the motor. It’s this force that is commonly referred to as boost. Boost is represented in psi (pounds per square inch). Typical boost is in the 5-10 psi range, although highly modified engines can see boost much higher than this typical range.

A centrifugal supercharger spins at very high speeds, thus, creating heat. To combat this, oil is required to lubricate it. Some centrifugal superchargers tap into the vehicle’s engine oil supply, while other centrifugal superchargers use oil that is self-contained in the supercharger. At specified intervals, the superchargers using self-contained oil must have their oil changed, just as you would also change your engine’s oil.

The two most commonly used centrifugal superchargers are Paxton and Vortech, although there are still many other manufacturers to choose from. It should also be noted that a centrifugal supercharger and a turbo share the same basic operational concept. The chief difference is that the centrifugal supercharger is driven by the engine’s accessory belt system, and a turbocharger is driven by the engine’s exhaust.

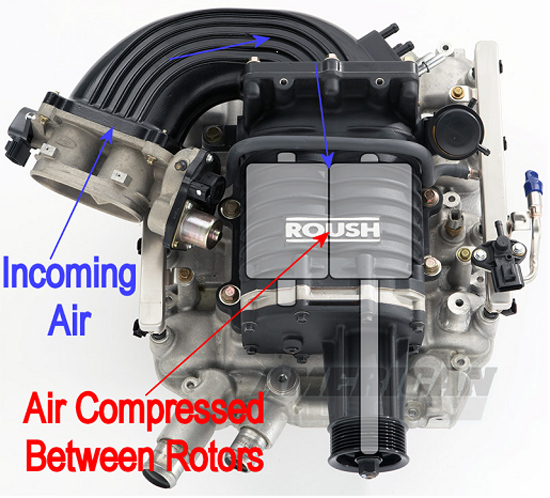

Postiive Displacement SuperchargersPositive displacement superchargers are easily recognized, as they sit directly on the motor itself. Normally this is directly on the top of the engine, as it does with the Mustang. There are some exotic cars, however, that use a positive displacement supercharger mounted more along the side of the engine. The first positive displacement supercharger on record was the Roots-type supercharger, which has origins dating back to the mid-1800’s.

The Roots-style supercharger is beginning to lose favor compared to the twin-screw (Lysholm) superchargers. This is primarily due to efficiency benefits with the twin-screw design. The twin-screw rotors use very tight tolerances to pull the air into the heart of the supercharger and compress it. Twin-screw designs also compress the air better than the rounded lobes of the Roots-style supercharger, which provides a better air charge when compared to power needed to turn the rotors. The Roots-style supercharger uses a more rounded-style lobe with tolerances that aren’t as tight as the twin-screw’s rotors.

A positive displacement supercharger still uses the basic supercharger concept of compressing air and overcoming the engine’s vacuum, but achieves this is a slightly different way than the centrifugal supercharger does. With a positive displacement supercharger, air enters it, and ends up at the rotors. From there, the rotors (whether twin-screw or the rounded Roots-style) compress the air as they spin inside the supercharger. The rotors are powered by a pulley at the front of the supercharger that is driven by the engine’s accessory belt system.

Depending upon the exact type of positive displacement supercharger, there may be more than two rotors used. With the modern positive displacement superchargers used on Mustangs, twin rotors are normally employed. Just as with the centrifugal supercharger, the rotors spin at high speeds and lubrication is required inside the supercharger. Positive displacement nearly always use a self contained oil system, which will requires oil changes on a regular basis.

When the air reaches the rotors, they compress it, forcing it out the underside of the supercharger’s body. From there, it enters directly into the intake of the engine. As with the centrifugal supercharger, you’ll see a minimum of 5-10 psi of boost with modified and strengthened motors, often sporting much more boost.

As a result of the benefits of twin-screw rotor use, the positive displacement industry as a whole has been moving towards twin screw designs in recent years. Regardless of the design approach used, the positive displacement supercharger has one distinct advantage over the centrifugal superchargers. That advantage involves the production low-end torque. Since a positive displacement supercharger delivers an almost constant flow of air once it’s called upon, the power gained from the supercharger is nearly instantaneous, unlike the centrifugal type, which tends to apply the power more gradually as the RPM increases and reaches a certain range.

Other Common Supercharger Components

Blow-Off Valve

A blow-off valve is used to relieve boost pressure. Boost is created as throttle input is increased, and the engine’s RPM begins to increase. If throttle input is decreased, the boost pressure must be relieved. A blow-off valve allows this pressure to be vented to the atmosphere, and not enter the engine’s intake when it’s not needed. Sometimes with smaller boost installations of 5 psi, a blow-off valve may not be used. As boost pressure increases, however, the ability to relieve the boost pressure becomes increasingly important, as engine damage could result.

Bypass Valve

The blow-off valve is sometimes incorrectly referred to as the bypass valve, however, there is a difference between the two. To increase the efficiency of positive displacement superchargers, some manufacturers will allow some air to bypass the supercharger’s rotors at lower engine RPM speeds. This equalizes the pressure on both side of the rotors and increases the efficiently of the supercharger when boost is not required. This comes into play at cruising speeds or slow acceleration; basically, times when very little throttle is being used.

Intercooler

One of the side effects of the way superchargers work is that, when it’s compressing the incoming air, it also heats that same air being compressed. That lessens the denisty of the air some, and can potentially increase the heat in the engine. To combat this, an intercooler is often used. The intercooler is typically placed after the supercharger, and the compressed air is forced through it. Intercoolers are fed by engine coolant most of the time, although some race setups have the ability to facilitate the use of ice. While the fact that the air passing through the intercooler will cause some minor loss of boost pressure, the benefits of cooling the incoming air far outweigh the disadvantages of an intercooler.

A centrifugal supercharger uses an intercooler that is placed into the piping that connects the supercharger to the intake. In the case of a positive displacement supercharger, the intercooler is placed between the supercharger and the motor. The air exits the underside of the positive displacement supercharger, and is moved through the intercooler and then into the intake. Sometimes the intercooler is also referred to as a heat exchanger.

As a sidenote, a typical intercooler in use today would be more appropriately referred to as an “aftercooler”, since it cools the air after it has been compressed. Early intercoolers were placed before the supercharger/turbocharger, and used normal airflow to cool the incoming aircharge. The name "intercooler" has stuck through the years, and persists to this day.

Advantages and Disadvantages of Superchargers as a Power Adder

The chief disadvantage to a supercharger is that the incoming air is heated as it’s compressed. Nitrous, as a power adder, doesn’t have this disadvantage, as cooling is a side effect of the change nitrous undergoes when it switches from a liquid to a gas. Superchargers are always driven by the engine as well, adding a small amount of load on the engine, even if they aren’t producing boost. While the use of a bypass valve has helped with this aspect, there is still a small impact to fuel economy.

A supercharger has several advantages in its favor, however. The first of these is the fact that, unlike with nitrous, bottle refills are not necessary. The power provided by a supercharger is also always ready, requiring nothing more that the throttle to be opened up. Because of this, and the fact that the use of nitrous on the street may be illegal on some areas, supercharging is one of the most popular options for street-driven Mustangs. The supercharger may seem expensive at first, but when it comes to weighing the horsepower gained by dollar spent, it’s quickly seen as a much more viable option than replacing engine components. It’s also a much quicker install than diving into and changing parts of the motor as well, as most supercharger installations aren’t too difficult, although tuning after the fact may be required.