- Shop All

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Coyote Engine Conversion Parts

- Reservoirs & Tanks

- Crate Engines & Blocks

- Serpentine Belts

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Body Kits

- License Plates & Frames

- Bras

- Light Covers

- Bumper Inserts

- Lightbars & Styling Bars

- Caliper Covers & Paint

- Louvers

- Car Covers

- Mud Flaps

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Paint & Headlight Protection Film

- Decals

- Pre-painted Parts

- Decklid Panels

- Racing Stripes

- Door Handles, Covers & Bezels

- Scoops

- Emblems & Badges

- Spoilers

- Exterior Trim

- Taillight Trim/Bezels

- Fuel Doors

- Wheel Accessories

- Grilles

- Wind Deflectors

- Hood Pin Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 2010-2013

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Reservoirs & Tanks

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets & Seals

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Bras

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals & Stripes

- Paint & Headlight Protection Film

- Decklid Panels

- Pre-Painted Parts

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Scoops

- Exterior Trim

- Spoilers & Wings

- Fuel Doors

- Taillight Trim

- Grilles

- Wheel Accessories

- Hood Pins & Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 2005-2009

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Reservoirs & Tanks

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets & Seals

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Bras

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals & Stripes

- Paint & Headlight Protection Film

- Decklid Panels

- Pre-Painted Parts

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Scoops

- Exterior Trim

- Spoilers & Wings

- Fuel Doors

- Taillight Trim

- Grilles

- Wheel Accessories

- Hood Pins & Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1999-2004

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Motor Mounts

- Alternators

- Nitrous Kits

- Batteries

- Oil Pans

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Replacement Serpentine Belts

- Cylinder Heads & Valvetrain

- Reservoirs & Tanks

- Engine Dressup

- Shaker Systems

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Mass Air Flow Meters/Sensors

- Exhaust

- Exterior

- Antennas

- Hood Pins

- Bras

- Hoods

- Bumper Inserts

- License Plates & Frames

- Caliper Covers

- Lightbars & Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals

- Racing Stripes

- Decklid Panels

- Scoops

- Door Handles, Covers & Bezels

- Spoilers & Wings

- Emblems & Badges

- Taillight Trim & Bezels

- Exterior Trim

- Wheel Accessories

- Fuel Doors

- Window Tint & Light Tint

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1994-1998

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Cylinder Heads & Valvetrain

- Replacement Serpentine Belts

- Engine Dressup

- Reservoirs & Tanks

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Exhaust

- Exterior

- Antennas

- Hood Pins & Kits

- Bras

- Hoods

- Bumper Inserts

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Racing Stripes

- Decals & Stripes

- Scoops

- Door Handles, Covers & Bezels

- Spoilers & Wings

- Emblems & Badges

- Taillight Trim & Bezels

- Exterior Trim

- Wheel Accessories

- Fuel Doors

- Window Tint & Light Tint

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1979-1993

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Cylinder Heads & Valvetrain

- Replacement Serpentine Belts

- Engine Dressup

- Reservoirs & Tanks

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Exhaust

- Exterior

- Antennas

- Hood Pins & Kits

- Bumper Inserts

- Hoods

- Caliper Covers

- License Plates & Frames

- Car Covers

- Light Bars & Convertible Styling Bars

- Convertible Top Parts

- Louvers

- Decals & Stripes

- Mirrors & Mirror Covers

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Spoilers & Wings

- Exterior Trim

- Wheel Accessories

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

Underdrive Pulley Tech Guide

Underdrive pulleys are often one of the first modifications many people make to their Mustang. There’s a good reason for this, as they’re a relatively cheap upgrade when comparing performance return per dollar spent. Aside from the power-related benefit, you’ll possibly gain an appearance improvement under the hood as well. Certain years of the Mustang use a crankshaft pulley that is designed to flash rust as a protective coating. While the rust doesn’t affect the strength of the pulley, it certainly doesn’t enhance the appearance of it, and your vehicle.

HistoryUnderdrive pulleys have been around for decades, but it wasn’t until the mid-to late 80’s when they came to the attention of mainstream enthusiasts. Prior to that, underdrive pulleys were only commonly seen in purpose built race cars dating back to the 50’s and 60’s. These cars used highly modified engines that ran at a high RPM for longer periods of time than just a simple trip down the drag strip. The pulleys were used to prevent the vehicles accessories for being driven too hard at the higher RPM’s, which would damage them. A damaged accessory, such as an alternator or water pump, could potentially cost the driver the race.

With the introduction of a single serpentine belt becoming common in the 80’s, the idea of using underdrive pulleys to enhance the performance of street cars was born. While the underdive pulley is most commonly associated with the 5.0 Fox-Body Mustang, they were also available for several other vehicles as well.

How They WorkIt’s common knowledge that your engine powers your car. Many tend to forget, however, that the engine performs other functions as well. It charges the battery by spinning the alternator, cools the engine by spinning the water pump, and makes steering easier by turning the power steering pump. The end result is that you lose a little bit of horsepower to your wheels due to the fact that the engine also has to power these accessories as well.

Obviously, you can’t avoid powering these accessories on a street car; at least not without adverse side effects. So you’re left with the possibility of reducing how much power the engine uses to turn the accessories. This is exactly what an underdrive pulley is designed to do.

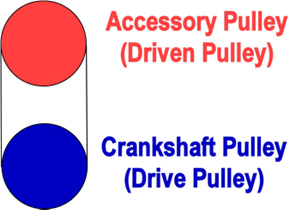

There are two ways to reduce the power the engine is using to turn the accessories. These methods would be to either increase the diameter of the accessory pulley, or decrease the diameter of the crankshaft pulley. To break this down so that’s easier to understand, let’s use the following diagram that shows a simple, two pulley setup for illustrative purposes.

In this simplified example, we see a two-pulley setup, where both pulleys are the same size. If the crankshaft (the drive pulley) makes one revolution, the belt will spin the accessory pulley (the driven pulley) one complete turn as well. So, you have a true 1:1 ratio between the two pulleys.

Now, let’s move onto the second example…

This time, the crankshaft pulley is smaller than the accessory pulley. For simplicities sake, even though this diagram isn’t to scale, we’ll say the crankshaft pulley is half the size of the accessory pulley. Since the crankshaft pulley drives the accessory pulley, it must fully rotate several times before the accessory pulley rotates a full turn. So as the engine is turning at 3000 RPM, the accessory is being rotated slower, which in turn, reduces parasitic drag from the accessory, as the engine doesn’t have to spin that particular accessory as fast.

As mentioned earlier, to accomplish this, you can change either the crankshaft pulley or the accessory pulleys. As there is more than one accessory that often needs to be underdriven, pulley kits start with a smaller crankshaft pulley. This gets all of the accessories close to the underdriven goal, with a single pulley change.

There’s a little more to the equation, however, than simply changing a single pulley and being able to tear up the road while enjoying your newfound power. This is why kits include more than one pulley. You can only underdrive your accessories to a certain point without potential side effects. So, in order to fine tune the ratio between the crankshaft and accessories, you are often provided with one or more additional pulleys, to either bring the accessory speed back up slightly, or reduce it down a little more than the other accessories, if it’s still possible to do so and still have them operate properly.

Potential Side EffectsSo now that you understand how a set of underdrive pulleys work and you’re ready to place an order. Before you load up your Shopping Cart and whip out your credit card, first step back and analyze your situation a little.

For most automotive enthusiasts, underdrive pulleys should not cause any issues at all. This is due to the fact that the auto manufacturers provide a certain level of accessory operation that exceeds normal needs. If you have installed aftermarket parts that would force the accessories roles to be more important, however, you may be utilizing more of that extra “buffer” than the manufacturer provides. A perfect example of this would be high-powered aftermarket stereo equipment, which can tax the factory alternator or even require a higher-powered alternator. So it’s important to weigh your particular situation first.

When it’s all said and done, most people will find that there is no downside to installing underdrive pulleys. For those enthusiasts, a pretty straightforward pulley swap is all that stands between them and a car that has an increased responsiveness, as well as a little more power!

Dylan I.

Nathaniel F.

Charles M

William L

Benjamin T

Johann S

Warren M

Ronald M

Jim G

Kristen H

Michael N

Jaime C

Alex G

Stacey H

Richard S

Josh W

Ricky I

Phillipe D

Greg W

Erin O

Dustin P

Heather W

Deborah L

Anthony A

Kenny O

Chris G

Bruce C

Kelvin A

Ronald H

Brian T

Anthony E

Daniel B

Ricky I

Linda W

Michael M

Emir H

Doug B

Chris G

Louis D

William S

Stefan O

Johnny B

James J

Noah B

Mac S

Richard M

Dennis S

Noah B

Richard M

Eric J

Michael A

Spencer T

Robert R

Sara A

William B

Erik S

James R

Kary K

John N

Emir H

Jonathan B

Sherry C

Josh W

William N.

Stratis R

Leo S

Joseph W

James C

George Y

Stephen C

David L

Richard A

Charles M

Albert B

Kyle P

Jim W

Walt S

Ronald B

Stephen H

Carlos G

Paul C

Aaron W

Robert S

Valerie J

Richard A

Ernesto C

Robert R

Steven T

Greg M

Jordan C

Ryan D.Customer Support

I grew up a Chevy kid, but when it came time to get a muscle car of my own, I fell in love with Mustangs. Been bleeding blue ever since. Being a Customer Service Rep at American Muscle lets me talk about the cars I love and how to make...

DaveTraining Director

I have been toying with Mustangs since before a driver's license was even an option. I've owned somewhere around 15 and I'm not done by a long shot. It all started with a 175 HP pearl white convertible Fox Body. It sparked my love for Mustang's and that sparked a...

BillCustomer Support

I'm currently a student at Penn State University studying political science. I've run a performance shop on the side for over a year now, and I've been working on cars for 7 years now. I've done transmissions, engines, and suspensions on many different cars. I used to be a Chevy...

GerryCustomer Support

When I retired after working for the city of Philadelphia and Septa I decided it was time to relive my earlier years and buy a real muscle car. (I also took on this job at AmericanMuscle for fun - I love the car and the community and belong to several...

KarenCustomer Support

I am a Mustangaholic. Do not try to cure me, I am perfectly OK with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was...

DuncanMarketing

Got into cars when I was young. Always was into the Mustangs because of the movie 'Gone in 60 Seconds' with the 1967 Shelby GT500 Fast back when I was growing up. I am currently attending Universal Technical Institute for Automotive/Diesel and Ford Fact program. I just started working at...

DannBama Tuning Specialist

I may be the only person to ever brave a winter with drag radials on a Mustang, while still daily driving it. Don’t worry, I finally got them off in the spring (day late and a dollar short, right?), and I promptly finished those tires at our company picnic in...

CraigProduct Development

I have always been around Mustangs in my professional life, either fixing them as a mechanic, selling them at dealerships, or modding them here at AmericanMuscle. Instead of starting right away with the power mods, I started looking more into suspension and weight reduction. I have always dreamed of entering...

LeeCustomer Support

I am a diehard Mustang fanatic. I first fell in love with Mustangs when I was 15 years old and I found a 1966 Mustang coupe restoration project. That was the beginning of my addiction. I quickly added a 1993 Mustang LX 5.0 to my collection which served as my...

JamieCustomer Support

This whole story starts when I was 15 and I had to have a foxbody. So I went out and found the loudest fastest foxbody that 5 grand could buy. When I realized that this thing was a certain death trap I sold it and moved onto the 2000 GT...

HeatherCustomer Support - Lead

I went to automotive school in Exton, PA, and worked as a mechanic for a while. My dad is a huge Ford guy; he used to drag race and my uncles raced motorcycles so I was always in the garage growing up. Working here is nice because it's not as...

Ryan MBama Tuning Specialist

I got my first Mustang when I was 16, a two tone 91 GT red and silver with a sunroof that didn’t leak! And needless to say I was a bit timid to do work on it, I hadn’t modified any vehicle before outside of installing a CD player. I...

DrewCustomer Support

Recently I bought my first home, the selling point for the house was not the amount of land, bedrooms, or bathrooms like how most people would choose a home. I made my choice based on the garage where the mustang sleeps. The garage is completely finished with painted floors, walls,...

Mike JCustomer Support - Manager

My first car was a 1989 Ford Mustang Saleen Convertible that I used as my test car to learn about working on Mustangs. Foxbodies have become my passion and now I pretty much consider myself a Foxbody expert. My dream project car is a Foxbody with a 03-04 cobra swap...

KarenCustomer Support

I am a Mustangaholic. Do not try cure me, I am perfectly ok with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was 13....

BrickPurchasing

I was a customer first - 7 years ago I came in to buy parts, got in an argument with someone about a part, and won. I left with my parts and a new job and I've been here ever since. I knew when I came to work at AmericanMuscle,...

JeffMarketing

I've loved Mustangs for as long as I can remember. My dad was a Camaro guy growing up, but his first work truck was a Ford, and we've been a Ford-only family ever since. My dad is a sheet metal worker/mechanic, so everything I know about my car I learned...

DanCustomer Support

All my other cars were all-wheel drive, my brother had an 04 cobra and i wanted to compete and beat him with naturally aspirated so i went with a mach1 - and beat him. Now he works here too! I got lucky and was able to find one of the...

SandyOperations

I have only driven 2 manual transmission Mustangs, the 1st was the car that taught me how to drive stick shift. The other is my current daily driver. A very memorable moment about my GT500 happened when I purchased a JLT CAI and SCT tuner. I thought the car was...

KarenCustomer Support

I am a Mustangaholic. Do not try cure me, I am perfectly ok with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was 13....

Chris RMarketing

I was raised by a car family. Drag racing and the Ford blue oval were always a huge part of our household. During my high school years, working on cars and participa....err watching street races probably helped further pull my focus from my priorities and I was hooked. After high-school...

LeeCustomer Support

I am a diehard Mustang fanatic. I first fell in love with Mustangs when I was 15 and I found a 1966 Mustang coupe restoration project. That was the beginning of my addiction. When it came time for my wife to get a new car, she had already driven my...

MikeLead Calibrator & Ford Performance Expert

I’ve had 18 Mustangs, ranging from a stock 66 coupe to a low 9-second Fun Ford Weekend” Street Renegade 96 GT that made 888 RWHP. (308 cid motor, Edelbrock heads, intake and topped off with a Paxton Novi 2000R supercharger pushing 30 psi of boost). My best pass in that...

BrianContent Development

Mustangs hold a special place in my heart. My father owned a 65 mustang when he was younger, but a friend wrecked it. The grille pony still sits on his workbench. Until getting my own pony, I had no clue why he would keep a metal horse for so long....

JamieCustomer Support

This whole story starts when I was 15 and I had to have a foxbody. So I went out and found the loudest fastest foxbody that 5 grand could buy. When I realized that this thing was a certain death trap I sold it and moved onto the 2000 GT...

GerryCustomer Support

When I retired after working for the city of Philadelphia and Septa I decided it was time to relive my earlier years and buy a real muscle car. (I also took on this job at AmericanMuscle for fun - I love the car and the community and belong to several...

EthanInventory Control

I've worked here for 3 years now and done pretty much everything in the warehouse from mounting and balancing wheels/tires, driving the forklift, shipping, and receiving. Both my brothers worked here in other departments, keeping it in the family! My car philosophy's pretty simple, I just want to get where...

EXPLORE

CUSTOMER SERVICE

Sign up for Exclusive Deals & Offers

Connect