- Shop All

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Coyote Engine Conversion Parts

- Reservoirs & Tanks

- Crate Engines & Blocks

- Serpentine Belts

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Body Kits

- License Plates & Frames

- Bras

- Light Covers

- Bumper Inserts

- Lightbars & Styling Bars

- Caliper Covers & Paint

- Louvers

- Car Covers

- Mud Flaps

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Paint & Headlight Protection Film

- Decals

- Pre-painted Parts

- Decklid Panels

- Racing Stripes

- Door Handles, Covers & Bezels

- Scoops

- Emblems & Badges

- Spoilers

- Exterior Trim

- Taillight Trim/Bezels

- Fuel Doors

- Wheel Accessories

- Grilles

- Wind Deflectors

- Hood Pin Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 2010-2013

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Reservoirs & Tanks

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets & Seals

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Bras

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals & Stripes

- Paint & Headlight Protection Film

- Decklid Panels

- Pre-Painted Parts

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Scoops

- Exterior Trim

- Spoilers & Wings

- Fuel Doors

- Taillight Trim

- Grilles

- Wheel Accessories

- Hood Pins & Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 2005-2009

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Reservoirs & Tanks

- Cylinder Heads & Valvetrain

- Shaker Systems

- Engine Dressup

- Superchargers

- Fender Covers

- Throttle Bodies

- Fuel Delivery

- Turbochargers

- Gaskets & Seals

- Underdrive Pulleys

- HVAC Parts

- Valves, Sensors & Sending Units

- Ignition Parts

- Water Pumps & Accessories

- Intake Manifolds & Plenums

- Exhaust

- Exterior

- Antennas

- Hoods

- Bras

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals & Stripes

- Paint & Headlight Protection Film

- Decklid Panels

- Pre-Painted Parts

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Scoops

- Exterior Trim

- Spoilers & Wings

- Fuel Doors

- Taillight Trim

- Grilles

- Wheel Accessories

- Hood Pins & Kits

- Window Tint & Light Tint

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1999-2004

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Motor Mounts

- Alternators

- Nitrous Kits

- Batteries

- Oil Pans

- Camshafts

- Radiators, Hoses & Accessories

- Cold Air Intakes

- Replacement Serpentine Belts

- Cylinder Heads & Valvetrain

- Reservoirs & Tanks

- Engine Dressup

- Shaker Systems

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Mass Air Flow Meters/Sensors

- Exhaust

- Exterior

- Antennas

- Hood Pins

- Bras

- Hoods

- Bumper Inserts

- License Plates & Frames

- Caliper Covers

- Lightbars & Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Mud Flaps

- Decals

- Racing Stripes

- Decklid Panels

- Scoops

- Door Handles, Covers & Bezels

- Spoilers & Wings

- Emblems & Badges

- Taillight Trim & Bezels

- Exterior Trim

- Wheel Accessories

- Fuel Doors

- Window Tint & Light Tint

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1994-1998

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Cylinder Heads & Valvetrain

- Replacement Serpentine Belts

- Engine Dressup

- Reservoirs & Tanks

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Exhaust

- Exterior

- Antennas

- Hood Pins & Kits

- Bras

- Hoods

- Bumper Inserts

- License Plates & Frames

- Caliper Covers

- Light Bars & Convertible Styling Bars

- Car Covers

- Louvers

- Chin Spoilers

- Mirrors & Mirror Covers

- Convertible Top Parts

- Racing Stripes

- Decals & Stripes

- Scoops

- Door Handles, Covers & Bezels

- Spoilers & Wings

- Emblems & Badges

- Taillight Trim & Bezels

- Exterior Trim

- Wheel Accessories

- Fuel Doors

- Window Tint & Light Tint

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

- 1979-1993

- Sales & Specials

- Accessories

- Body Kits

- Brakes

- Drivetrain

- Engine

- Air, Oil & Fuel Filters

- Mass Air Flow Meters/Sensors

- Alternators

- Motor Mounts

- Batteries

- Nitrous Kits

- Camshafts

- Oil Pans

- Cold Air Intakes

- Radiators, Hoses & Accessories

- Cylinder Heads & Valvetrain

- Replacement Serpentine Belts

- Engine Dressup

- Reservoirs & Tanks

- Fender Covers

- Superchargers

- Fuel Delivery

- Throttle Bodies

- Gaskets & Seals

- Turbochargers

- HVAC Parts

- Underdrive Pulleys

- Ignition Parts

- Valves, Sensors & Sending Units

- Intake Manifolds & Plenums

- Water Pumps & Accessories

- Exhaust

- Exterior

- Antennas

- Hood Pins & Kits

- Bumper Inserts

- Hoods

- Caliper Covers

- License Plates & Frames

- Car Covers

- Light Bars & Convertible Styling Bars

- Convertible Top Parts

- Louvers

- Decals & Stripes

- Mirrors & Mirror Covers

- Door Handles, Covers & Bezels

- Racing Stripes

- Emblems & Badges

- Spoilers & Wings

- Exterior Trim

- Wheel Accessories

- Grilles

- Intake

- Interior

- Lights

- Restoration

- Suspension

- Tires

- Tuners

- Wheels

Upgrading Fox Chassis – Subframe Connectors

Believe it or not, the most important modification when upgrading your Foxbody does not add any power at all. The most important (and often over-looked) aspect when upgrading a Foxbody is the chassis itself. Subframe connectors are a necessity, even at stock power levels.

Why bother upgrading the chassis you might ask? Despite the fact that, yes, you are correct, stiffening the chassis does not add anymore power, there are a few significant reasons as to why it should be done. To begin, Fox Mustangs are a unibody design. In laymen's terms, this means 'weak' (but not bad!). In technical terms, it means that the car does not implement a full frame running the full length of the car. Rather, a major section of the car relies on subframes (smaller, weaker framing) and the floor pans to provide rigidity and strength to the vehicle. Imagine a unibody to be constructed of two frame sections, and these two sections are connected via the floor pans.

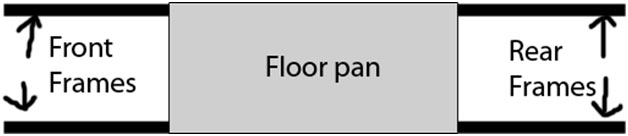

Unibody (looking from the bottom up)

As you can see (despite this being a super basic rendering), there seems to only be two real frame sections – at the front and at the back. They are joined simply by the floor pans. For contrast, examine a full frame (or body on frame) design.

Body on frame (looking from the bottom up)

This design has frame rails running the whole length of the vehicle, interconnected in multiple ways. This means it is strong! Think truck frames. These days, they can haul up to 22,000 lbs.

The Lowdown on Subframe Connectors

Now, Foxbody Mustangs are built using the first method, unibody construction. That 5.0L engine under the hood, even in factory trim at 225HP and 300 ft-lb of torque, is enough to twist and distort the subframes and floor pans with ease. Given enough time and a heavy enough foot, the subframes are guaranteed to deform. Start adding more horsepower to the equation without sufficiently bracing the chassis and a slight issue quickly becomes a big issue. How do you combat this? Again, aftermarket performance parts have come to the rescue! The aftermarket has long since recognized this vulnerability within the Foxbody platform and consequently come up with an affordable and efficient way to dealing with this chassis twist and torsion. The solution you ask – subframe connectors (often referred to simply as SFC’s by the young, hip forum homies, yo). Essentially, subframe connectors are going to link the front subframe with the rear subframe and attach to the floor pans, adding much needed structural integrity across the vehicle.

When shopping for subframe connectors, there are a few factors to consider. Many companies manufacture subframe connectors but there are three that stick out. J&M, Maximum Motorsports and Steeda are very reputable companies and all three produce high quality subframe connectors popular amongst modified Mustang owners. Furthermore, their parts are perfectly engineered to fit the exact geometry of Foxbody Mustangs (actually, any Mustang from 1979-2004). The benefit of this is less hassle when installing because they are designed to be a perfect fit – not a generic, multi-vehicle part. Amongst the options to consider are weld-in or bolt-on subframes connectors and full-length or partial-length. Decisions, decisions… let’s address them, starting with the option of weld-on or bolt-on.

Weld-on vs Bolt-on

As the name implies, the difference between these two are installation method. Weld-on’s are trickier and more costly to install because they will need to be brought to a shop capable of welding them in. Usually this isn’t free (unless you can weld). Bolt-on’s, on the other hand, can be done by any Jim, John and Jack with a wrench and the ability to follow printed instructions. Performance wise, weld-on’s are the number one choice and are highly recommended. Bolt-on’s have ease of installation on their side, but they will not offer anything close to the rigidity and bracing that a proper set of welded SFC’s will. For this reason, it is highly recommended to pick weld-on over bolt-on.

Full-length vs Partial-length

Some companies offer partial-length subframe connectors as a way to reduce the price of the connectors. Like bolt-ons, partial-length won’t give the same stiffness as full-length. In fact, the idea of a partial-length SFC is a little redundant. The point of subframe connectors is to tie the front and rear subframes together. Opt for full-length instead.

The Finale

What will happen once you’ve equipped your Pony with the much needed subframe bracing? As said before, you won’t make any extra power, but you may go a little faster. SFC’s help with traction by transmitting power from the engine to the wheels instead of some power being wasted by twisting the frame. They also help the car corner better and overall will give a much solider feel. They lay the foundation for a much more powerful car, without fear of tearing the frame in two.

-CMC

Dylan I.

Nathaniel F.

Charles M

William L

Benjamin T

Johann S

Warren M

Ronald M

Jim G

Kristen H

Michael N

Jaime C

Alex G

Stacey H

Richard S

Josh W

Ricky I

Phillipe D

Greg W

Erin O

Dustin P

Heather W

Deborah L

Anthony A

Kenny O

Chris G

Bruce C

Kelvin A

Ronald H

Brian T

Anthony E

Daniel B

Ricky I

Linda W

Michael M

Emir H

Doug B

Chris G

Louis D

William S

Stefan O

Johnny B

James J

Noah B

Mac S

Richard M

Dennis S

Noah B

Richard M

Eric J

Michael A

Spencer T

Robert R

Sara A

William B

Erik S

James R

Kary K

John N

Emir H

Jonathan B

Sherry C

Josh W

William N.

Stratis R

Leo S

Joseph W

James C

George Y

Stephen C

David L

Richard A

Charles M

Albert B

Kyle P

Jim W

Walt S

Ronald B

Stephen H

Carlos G

Paul C

Aaron W

Robert S

Valerie J

Richard A

Ernesto C

Robert R

Steven T

Greg M

Jordan C

Ryan D.Customer Support

I grew up a Chevy kid, but when it came time to get a muscle car of my own, I fell in love with Mustangs. Been bleeding blue ever since. Being a Customer Service Rep at American Muscle lets me talk about the cars I love and how to make...

DaveTraining Director

I have been toying with Mustangs since before a driver's license was even an option. I've owned somewhere around 15 and I'm not done by a long shot. It all started with a 175 HP pearl white convertible Fox Body. It sparked my love for Mustang's and that sparked a...

BillCustomer Support

I'm currently a student at Penn State University studying political science. I've run a performance shop on the side for over a year now, and I've been working on cars for 7 years now. I've done transmissions, engines, and suspensions on many different cars. I used to be a Chevy...

GerryCustomer Support

When I retired after working for the city of Philadelphia and Septa I decided it was time to relive my earlier years and buy a real muscle car. (I also took on this job at AmericanMuscle for fun - I love the car and the community and belong to several...

KarenCustomer Support

I am a Mustangaholic. Do not try to cure me, I am perfectly OK with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was...

DuncanMarketing

Got into cars when I was young. Always was into the Mustangs because of the movie 'Gone in 60 Seconds' with the 1967 Shelby GT500 Fast back when I was growing up. I am currently attending Universal Technical Institute for Automotive/Diesel and Ford Fact program. I just started working at...

DannBama Tuning Specialist

I may be the only person to ever brave a winter with drag radials on a Mustang, while still daily driving it. Don’t worry, I finally got them off in the spring (day late and a dollar short, right?), and I promptly finished those tires at our company picnic in...

CraigProduct Development

I have always been around Mustangs in my professional life, either fixing them as a mechanic, selling them at dealerships, or modding them here at AmericanMuscle. Instead of starting right away with the power mods, I started looking more into suspension and weight reduction. I have always dreamed of entering...

LeeCustomer Support

I am a diehard Mustang fanatic. I first fell in love with Mustangs when I was 15 years old and I found a 1966 Mustang coupe restoration project. That was the beginning of my addiction. I quickly added a 1993 Mustang LX 5.0 to my collection which served as my...

JamieCustomer Support

This whole story starts when I was 15 and I had to have a foxbody. So I went out and found the loudest fastest foxbody that 5 grand could buy. When I realized that this thing was a certain death trap I sold it and moved onto the 2000 GT...

HeatherCustomer Support - Lead

I went to automotive school in Exton, PA, and worked as a mechanic for a while. My dad is a huge Ford guy; he used to drag race and my uncles raced motorcycles so I was always in the garage growing up. Working here is nice because it's not as...

Ryan MBama Tuning Specialist

I got my first Mustang when I was 16, a two tone 91 GT red and silver with a sunroof that didn’t leak! And needless to say I was a bit timid to do work on it, I hadn’t modified any vehicle before outside of installing a CD player. I...

DrewCustomer Support

Recently I bought my first home, the selling point for the house was not the amount of land, bedrooms, or bathrooms like how most people would choose a home. I made my choice based on the garage where the mustang sleeps. The garage is completely finished with painted floors, walls,...

Mike JCustomer Support - Manager

My first car was a 1989 Ford Mustang Saleen Convertible that I used as my test car to learn about working on Mustangs. Foxbodies have become my passion and now I pretty much consider myself a Foxbody expert. My dream project car is a Foxbody with a 03-04 cobra swap...

KarenCustomer Support

I am a Mustangaholic. Do not try cure me, I am perfectly ok with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was 13....

BrickPurchasing

I was a customer first - 7 years ago I came in to buy parts, got in an argument with someone about a part, and won. I left with my parts and a new job and I've been here ever since. I knew when I came to work at AmericanMuscle,...

JeffMarketing

I've loved Mustangs for as long as I can remember. My dad was a Camaro guy growing up, but his first work truck was a Ford, and we've been a Ford-only family ever since. My dad is a sheet metal worker/mechanic, so everything I know about my car I learned...

DanCustomer Support

All my other cars were all-wheel drive, my brother had an 04 cobra and i wanted to compete and beat him with naturally aspirated so i went with a mach1 - and beat him. Now he works here too! I got lucky and was able to find one of the...

SandyOperations

I have only driven 2 manual transmission Mustangs, the 1st was the car that taught me how to drive stick shift. The other is my current daily driver. A very memorable moment about my GT500 happened when I purchased a JLT CAI and SCT tuner. I thought the car was...

KarenCustomer Support

I am a Mustangaholic. Do not try cure me, I am perfectly ok with being one. I have owned over 10 Mustangs in my lifetime already. I currently have just 5 (I did own 8 at one time). I fell in love for the first time when I was 13....

Chris RMarketing

I was raised by a car family. Drag racing and the Ford blue oval were always a huge part of our household. During my high school years, working on cars and participa....err watching street races probably helped further pull my focus from my priorities and I was hooked. After high-school...

LeeCustomer Support

I am a diehard Mustang fanatic. I first fell in love with Mustangs when I was 15 and I found a 1966 Mustang coupe restoration project. That was the beginning of my addiction. When it came time for my wife to get a new car, she had already driven my...

MikeLead Calibrator & Ford Performance Expert

I’ve had 18 Mustangs, ranging from a stock 66 coupe to a low 9-second Fun Ford Weekend” Street Renegade 96 GT that made 888 RWHP. (308 cid motor, Edelbrock heads, intake and topped off with a Paxton Novi 2000R supercharger pushing 30 psi of boost). My best pass in that...

BrianContent Development

Mustangs hold a special place in my heart. My father owned a 65 mustang when he was younger, but a friend wrecked it. The grille pony still sits on his workbench. Until getting my own pony, I had no clue why he would keep a metal horse for so long....

JamieCustomer Support

This whole story starts when I was 15 and I had to have a foxbody. So I went out and found the loudest fastest foxbody that 5 grand could buy. When I realized that this thing was a certain death trap I sold it and moved onto the 2000 GT...

GerryCustomer Support

When I retired after working for the city of Philadelphia and Septa I decided it was time to relive my earlier years and buy a real muscle car. (I also took on this job at AmericanMuscle for fun - I love the car and the community and belong to several...

EthanInventory Control

I've worked here for 3 years now and done pretty much everything in the warehouse from mounting and balancing wheels/tires, driving the forklift, shipping, and receiving. Both my brothers worked here in other departments, keeping it in the family! My car philosophy's pretty simple, I just want to get where...

EXPLORE

CUSTOMER SERVICE

Sign up for Exclusive Deals & Offers

Connect